Hello: your methodology is OK, but rather than using an estimated time for pumpdown from the analytical equation you can actually SIMULATE the whole pumpdown, over the time length that you need.

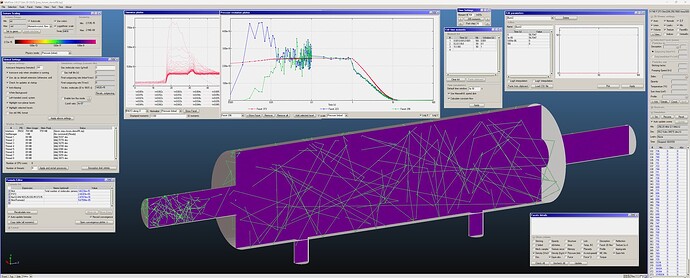

Since I do not have your detailed geometry, I’ll attach a sample file with time dependent calculations. In a real case you could even simulate the time dependent outgassing, if you can estimate it, by using the built in feature of a parameter file, and assigning it to all facets with time’dependent outgassing. Like this you can simulate the initial exponential decay (as per your equation) and then the 1/t pumpdown due to thermal outgassing (decreasing as 1/t) plus another phase proportional to 1/sqrt(t) (like water desorption)… and finally you may even add a constant outgassing at some locations (like permeation or leaks, virtual or not).

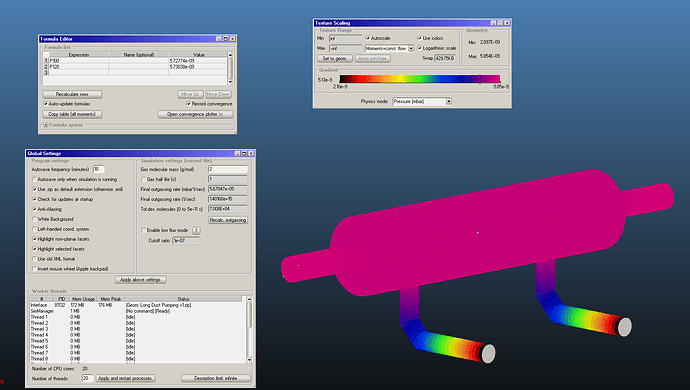

Here you can see a screenshot of the model I have made just looking at your screenshot, a 7x2 m cyl with 2x 5000 l/s pumps (connected via different geometry as compared to yours, for simplicity).

I send also here the link to the time-dependent simulation, the file makes 21 MB, so I can’t put it in attachment here, it’s a Dropbox link:

https://www.dropbox.com/scl/fi/tzrjdpyskelfdfo129zk9/joey_forum_demoRK.zip?rlkey=caprrs4vwn93b8lq14apthn8k&dl=0

Hope it works.

As you can see on the screenshot, I have defined a number of different length time periods (moments): I start with very short ones, 0.001s, up to 0.1 s (100 of them), thjen I go to 0.1 s interval, from 0.2 to 10 s (99 total), and then finally 1s interval from 11 s to 100 s (90 moments).

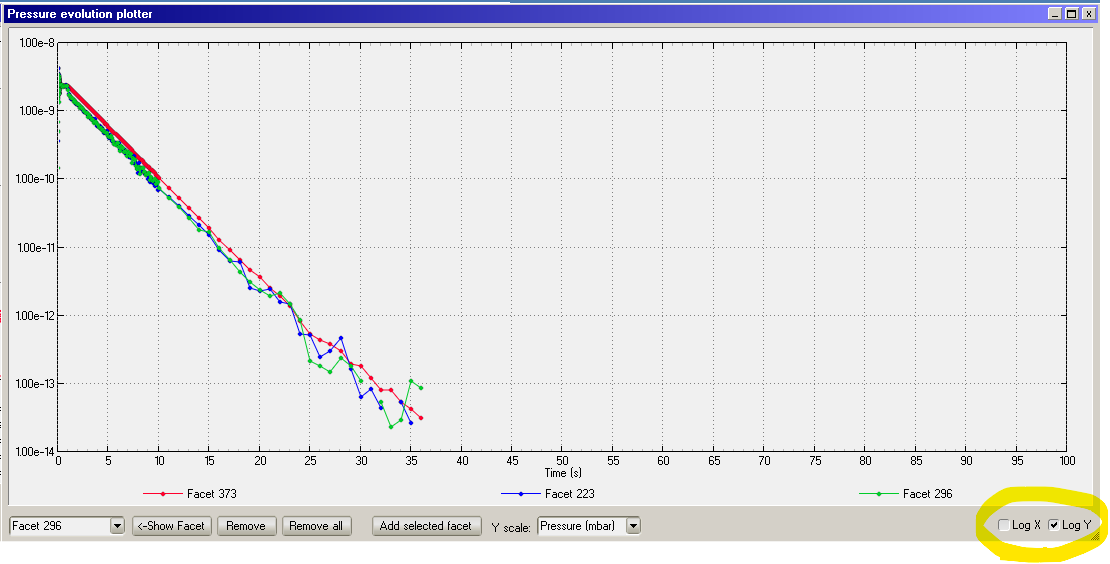

On the “pressure evolution plotter” you can see the average pressure evolution over 3 facets, namely: facet #373, which is the coloured one on the figure (a 2’sided, transparent facet, textured with texture size 5x5 cm, squares).

Then there are facet #223 and 296, which are the two PUMPING facets.

The outgassing I have set ONE facet only, a “burst” of 1E-6 s times 56.7047 mbar*l (See “Edit parameters” window on the upper right. I have taken this value from your screenshot, just to get ballpark numbers correct (although my geometry is not exactly yours). The desorbing facet is #147 (i.e. the end-cap of the bigger cylindrical body with a hole in the middle, on the left on the figure).

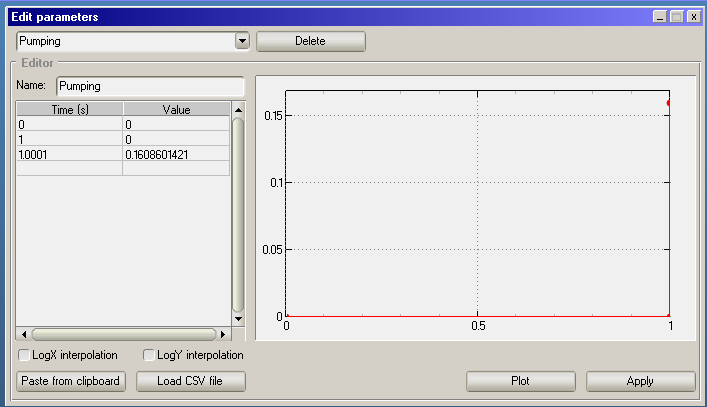

I have also defined a parameter call “Pumping” which sets the sticking coefficient of the two pumping surfaces to 0 until t=1 s, then it suddenly switches to the value corresponding to 5000 l/s for H2 gas, see the other figure here.

As you can see on the “Pressure evolution plotter” window the pressure starts from 0 (logical), then it increases, with an overshoot on facet #223 (blue line) nut then all 3 lines go to the same value, around 2.45E-9 mbar immediately before the pumping starts (1 s).

The 3 pressures then decrease in with separate curves, but if you look at them on a lin-log scale they have PARALLEL paths, and the linear (on a log vertical scale) slope is proportional to the S*t/V exponent in your formula… apart from the initial time when there is no pumping, of course.

See the third figure for “Pressure evolution plotter” in lin-log scales, here:

The advantage of this way of simulating the thing is that in principle one could have a time-dependent outgassing, as I said, and therefore one would have non constant slope on this graph.

I see now that the order of the figures is not correct, sorry… it is 2,3,1 as referenced in the text.

I stop here, if you have further questions or remarks to make please write back.

Cheers, and good luck.

R.