Dear Marton,

Some Molflow simulations produce precise results quickly, and some—particularly complex geometries or long systems—take many hours to generate sufficient statistics. As a user, my intuition is only a partial guide to which of these best describes a given simulation. I would appreciate a couple of tools to better understand and predict the time required to achieve results of a particular precision and accuracy.

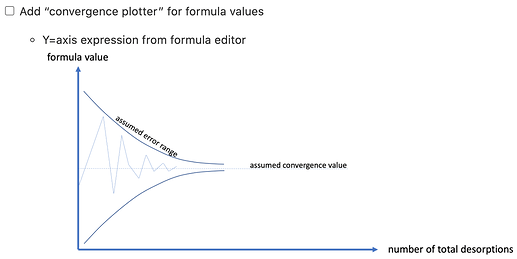

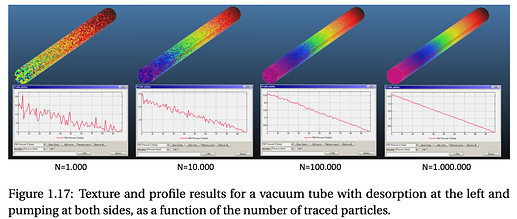

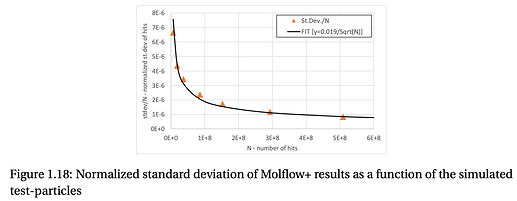

The first tool would let me define a metric for the precision of the results that’s relevant to my case. This might be the standard deviation of the pressure values in a facet’s texture, for example. The second tool would let me define a metric for the evolution of the results and their precision. This might be the relative change in the average pressure on a facet per second of simulation time; once the simulation has converged and the pressure is no longer evolving, I might wish to stop the simulation even if the accuracy—say, the standard deviation of the pressures across the facet—is still large.

Molflow could track, and save with the file, the history of the user-defined “accuracy” and “precision” metrics. Not only would this allow the user to understand how their simulation evolved, but it would also enable automated prediction, as follows. Regarding “precision”: if I want to reach a point where an average pressure is stationary, Molflow could fit the early part of the pressure-vs-simulation time curve and extrapolate (with some uncertainty, of course, that would decrease over time) to the point in time where to pressure ceases to evolve. For “accuracy,” Molflow could similarly track the standard deviation of the pressure across a facet versus simulation time and predict when it will reach some user-defined threshold. These tools would allow a user to understand whether they should come back after a cup of coffee or tomorrow morning.

In the context of scripting for Molflow, it would be valuable to have a “smart” way to stop a simulation job once the results are good enough. The accuracy and precision tools discussed above are excellent candidates for this behavior. The user could set the simulation to stop when the pressure (or other value) across a facet or set of facets (considered either individually or taken together) ceases to evolve and the standard deviation of that value is below a threshold. Molflow could then proceed to the next configuration in the script.

Thanks as always,

Alec