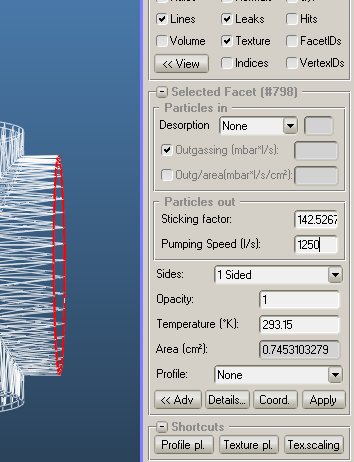

I tried to simulate the pressure of a high vacuum system. The system has four chambers and it contains 3 pumps. I create the geometry in autodesk inventer and upload the stl file in Molflow. And set the outg/area 10^-8 and then want to specify the pumping speed 1250l/s. But when i put 1250, sticking factor becomes greater than 1. I didn’t understand what is the problem. Please help to solve the problem.

Most likely the export/import units of the STL files don’t match and your Molflow dimensions are 10x smaller than the desired. Can you check?

The dimension of the system is around 1000 mm. In stl file all units are in mm. so during import in molflow i choose mm as unit.

On you screenshot, I can see that the pumping port is 0.745cm2, which would mean a diameter of 0.6cm, which is unrealistic.

If your pumping hole is really 0.745cm2 area, then the maximum theoretical pumping speed (i.e. that of a perfectly sticking pump) is

11.77l/s/cm2*0.745cm2=8.7l/s

The problem is solved. Thank you. But there is leak in one part of geometry. And i am not able to solve the same.