Hi,

last winter I started to study vacuum technology and now I’m working on to study a simple vacuum cavity (for RF test) and to design an appropriate pumping interface.

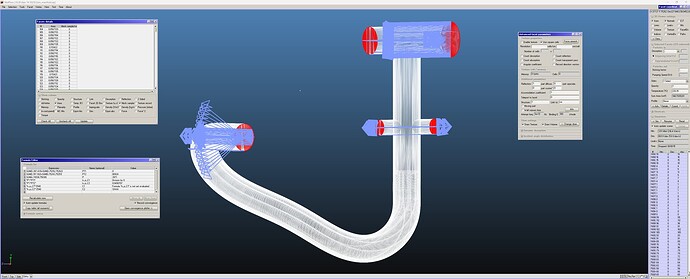

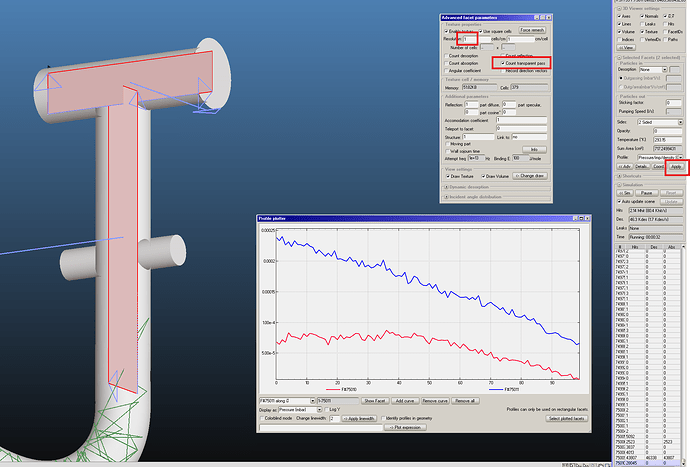

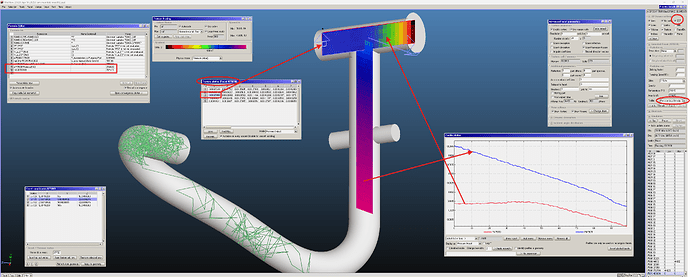

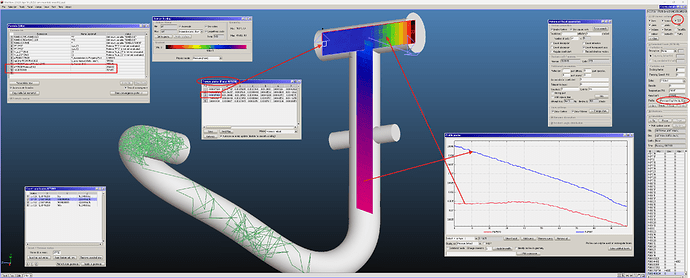

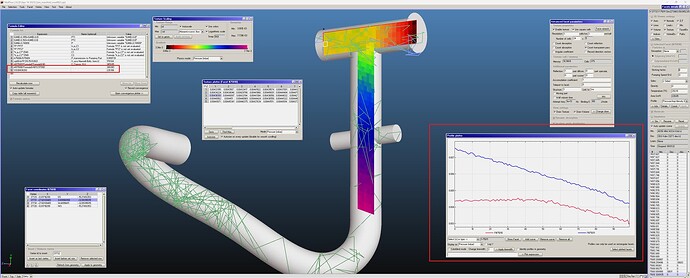

I designed a simple manifold made by two tee DN 63 according with the scheme in the figure attached. This solution allows me to pumpdown the cavity using one or two ports: one is connected directly to the cavity (P1); the second one using a pipe (P2).

I made the 3D model of the entire volume but also of the pumping interface only. I made a simple calculation of the conductance of the manifold (direct port-pump; pipe port-pump) considering the hypotesys of short pipe and long pipe respectively. Now, I want to determine the conductance between the manifold, not only to confirm my calculation (I know that there is an error between simulation and analitical calculation - generally no more than 10%) but also to understand how to analyze a complex pumping interface (sometimes difficult to calculate) and, in this case, if it is a good choice.

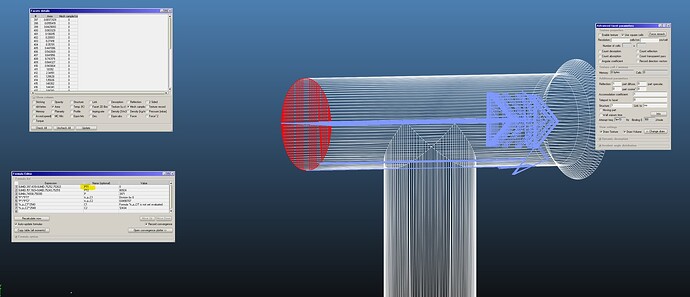

I prepared the simulation, as you can see in the file attached. I made this assumption:

- pump port: sticking factor 1;

- cavity port 1 (direct): desorption cosine 1, sticking factor 1;

- cavity port 2 (pipe): desorption cosine 1, sticking factor 1;

- gas: hydrogen.

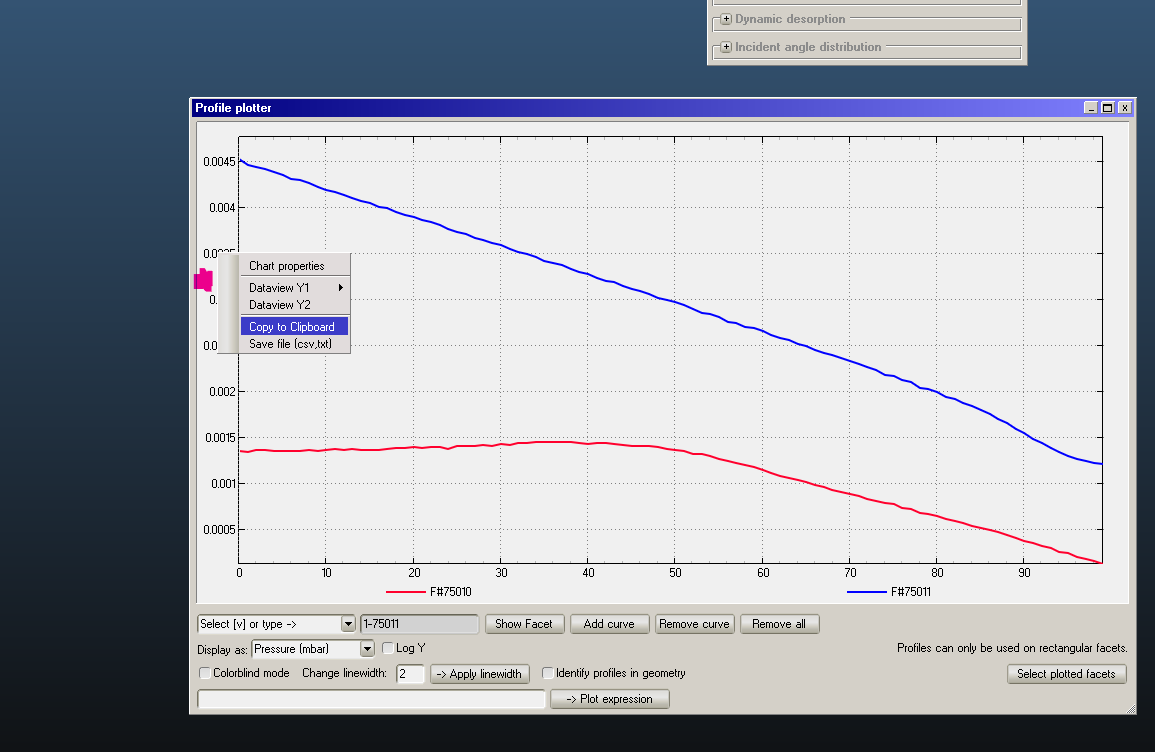

The transmission probability is calculated as usual: the ratio absorbe/desorbed considering the correct port for the desorption.

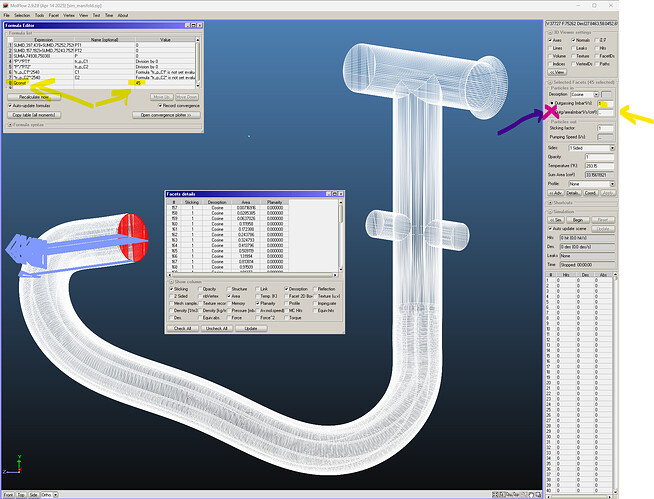

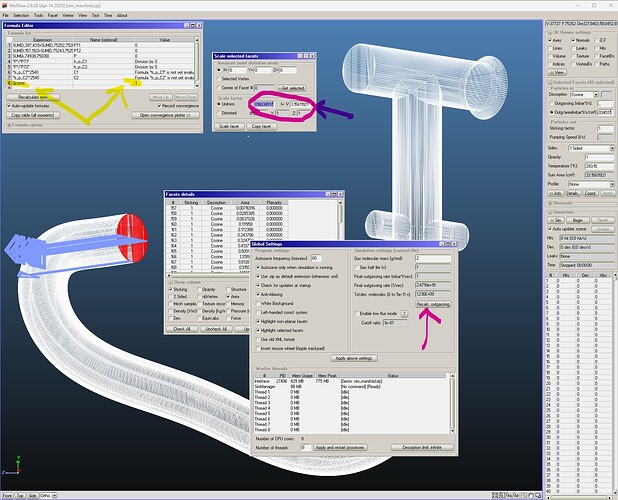

Now my the question are:

- if I set the desorption on both ports, the transmission probability is always the same for each coupler of ports. It is strange: maybe it is because the system is generating the same quantity of particle and at the end they are pumped away? It is correct, or I made some error or assumption? I still have some doubts.

- I considered one port at a time, and I found different conductance. This is correct but the for the short pipe I obtain a value double than the one calculated. I am not expecting some error Where I am going wrong?

sim_manifold.zip (4.2 MB)

Sorry for the long post. These are probably simple mistakes due to the fact that I am still inexperienced. But I think that is a good opportunity to learn.

Thanks a lot in advance for the help.