Here is my replying, detailing how to modify the original STL file with extra facets.

There are 44 screenshot in the attached zipped file (7zip), GalWinder.7z.

I’ll comment each one of them here below.

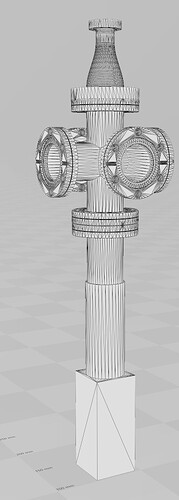

Test_signelfile_1.jpg: shows the STL file model before collapsing (number of vertices=3x number of facets), with volume ON: it has a lot more detail than necessary. Not only the vacuum surfaces, but also the external ones, flanges, holes for screws. I don’t know what units the CAD model was created with, I assume here mm… if not a proper scale factor will need to be used, easy to do within the graphical interface.

We must remove all the unnecessary facets.

One way would be to use a proper CAD tool, I believe that Marton has created a video or a file (on the Molflow website) where he explains how to use SpaceClaim.

I never use SpaceClaim because I never use CAD.

Here I show how to remove all unnecessary facets, modify the file, add some facets, etc… in order to get a workable 3D model, geometry only, to which the user would then add the physics, i.e. desorbing and pumping facets, temperatures, opacities, etc…

Test_signelfile_2.jpg: I zoom in and select a few facets with the mouse: (keep “shift” or “Ctrl” button pressed to add or subtract an highlighted facet to those already selected by mouse click). It is clear that the CAD model has all normal vectors pointing in the WRONG direction, outward for the inner vacuum surfaces and inward for the external ones. The CAD model describes the VOLUME of the object, the solid part, so it makes sense.

We need to revers ALL facets’ normals, easy to do, just select all facets (CTRL-a shortcut to select them all and then “Swap normal” command, “Facet” menu, or CTRL-n shortcut).

Once this is done it is better to save the file with a proper NON-STL extension, zip extension.

Test_signelfile_3.jpg: we now use the “Smart selection” command in the “Selection” menu, hit “Analyze” and then start clicking on the facets until a group of facets belonging to the EXTERNAL (useless) part of the model is highlighted. Here we see the first part of the first tube after the initial box. I select them and hit CTRL-delete (or “Delete” in the “Facet” menu).

Test_signelfile_4.jpg: I proceed in the same way for the next external layer, second part of the round tube… and delete the facets. You better save again the file, in case something goes wrong (there is no “restore” button for the delete action!). Change the name, in case you want to save all or most of the steps.

Test_signelfile_5.jpg and Test_signelfile_6.jpg: I select here two more external layers, and delete them, one at a time.

Test_signelfile_7.jpg: for the external facets of the rectangular box the smart selection does NOT select them with just one mouse click: that’s because the angular parameter in the “Smart selection” box is “30” (degrees), i.e. only adjacent facets having normal vectors differing by LESS than 30 degrees get selected simultaneously (a great and very useful routine written by Marton, kudos to him!).

Once I select the 5 facets (square end cap on the left in the figure and 4 rectangular side facets, I delete them.

Test_signelfile_8.jpg: I then do a number of facet selections (like repeating the previous steps for the remaining external facets of the 6-way cross, and the conical taper at the end), and I also select the FLANGES, which are not important (OK, they internal surface IS important, but we can re-created it later, easily, see below). When I do these (several) steps, I finally get to this model.

You can see that there are some missing parts (where the intermediate flanges where placed and at the top of 4 branches of the 6-way part. We need to fill in the missing parts, using the editing features of Molflow+.

Test_signelfile_9.jpg: to visualize what needs to be done, I set desorption ON from facet no. 3530, the square on the left, and NO sticking on any facet. Total outgassing rate of 1, any value would be equivalent at this stage, and if I hit “Run” button on the right I get this: one can clearly see the leaks… make sure you have the “Lines” and “Leaks” check boxes checked, upper right corner. We need to fill in the missing horizontal segments (two, one before and one after the 6-way cross), plus the termination (4 on the 6-way cross and the exit on the right (if that’s an exit… maybe there’s a pump there?).

Test_signelfile_10.jpg: to fill in the gap between the two horizontal circular pipe segments I select the vertices (press “Tab” while using the mouse to select all the necessary vertices, the mouse pointer will switch from a normal one to one with a little “v” on the right. If you want to deselect the vertices just click outside of the model while keeping “Tab” pressed.

If more vertices are selected in addition to those you need to create a facet, then you need to delete all the unused vertices, using the “Clear isolated” command (second one in the “Vertex) menu. Once you have all vertices you need selected, like in the figure, you can use the “Create Facet from Selected” command in the “Vertex” menu, with “Convex hull” option, and Molflow+ will generate the facet (if the resulting facet is NOT convex then it would not work, in that case you need to select SEQUENTIALLY all of the needed vertices and then use the other option, “Keep selection order”). Now I have created a new facet, which is appended at the end of the list of facets, no. 4244. I change its opacity to 0 (it is not a real, solid facet), otherwise it would later act as a plug, preventing molecules from moving left to right.

Test_signelfile_11.jpg: I repeat the operation with the other opening, selecting the vertices and hitting CTRL-v (shortcut for “Create facet from selected” in the “Vertex” menu). It is facet no.4245. Again, set its opacity to 0.

Test_signelfile_12.jpg: I select the two facets, and use now the “Facet”, “Transition between 2” command. It will create the transition between the two facets.

Test_signelfile_13.jpg: this shows the result…. 84 new triangular facets, with normal vectors pointing correctly INWARD, no need to reverse them.

Test_signelfile_14.jpg: here I have selected the vertices of the 4 terminations on the 6-way cross (one at a time!) and repeated the CTRL-v command, creating new facets. In case they come out wrongly oriented (outward) I use the CTRL-n normal reversal command, as before.

Test_signelfile_15.jpg: now I save the file, and run the program. The leaks have disappeared from the gap we had before, and only remain at the other gap and at the end. Occasionally few leaks appear at the interface between two segments of the same circular pipe, with apparently no axial gap… we’ll see later what is causing that, and how to fix it quickly.

Test_signelfile_16.jpg: here I repeat the same operation, twice, as before. I create the two end facets at the axial gap borders, vertex selection + CTRL-v, twice. Notice that the two new facets’ normal vectors are oriented antiparallel to each other, this means that when I’ll generate the transitional facets they will have the WRONG orientation, outward.

Test_signelfile_17.jpg: use of the “Transition…” command, as explained.

Test_signelfile_18.jpg: wrong normal, use CTRL-n.

Test_signelfile_19.jpg: run again, now leaks only at the exit on the right, and some intermediate ones (to be fixed later).

Test_signelfile_20.jpg: Select the end vertices and use CTRL-v to create the circular end facet.

Test_signelfile_21.jpg: now I switch to “Volume” view, and see that there are leaks on the interface connection, as mentioned earlier, and near the end of the tube… why is that?

Test_signelfile_22.jpg: I zoom in near the end. These leaks look strange…

Test_signelfile_23.jpg: Explanation (going back to wireframe view, “Volume” OFF): there is an overlapping of the last short cylindrical piece of pipe and the end of the tapered transition. (again visualized by letting “Smart selection” on (“Enable” checkbox checked).

Test_signelfile_24.jpg: I select some vertices and visualize their Z coordinate (the axis of this model is parallel to the Z axis).

Test_signelfile_25.jpg: I delete all the side facets of the short cylindrical stub, leaving the newly created end facet in place.

Test_signelfile_26.jpg: I create a transparent (opacity=0) facet at the end of the taper, as usual (vertex selection + CTRL-v command).

Test_signelfile_27.jpg: I use again the “Transition between 2” command to generate the side walls and fill in the gap.

Test_signelfile_28.jpg: wrong orientation of the normal vectors, outward, use CTRL-n again to reverse them.

Test_signelfile_29.jpg: run again. The leaks at the end have disappeared, only those at the interface of the two half pipes are left. Notice that some of the leaks have their origin point (point of emission of the molecule) away from the leaky holes, see few leak arrows on the right, near the conical taper.

Test_signelfile_30.jpg: same view in “Volume” mode. Leaks appear all around the interface perimeter… let’s see what is causing them…

Test_signelfile_31.jpg: I zoom in near the interface: it is clear that the definition of the two half pipes are not the same, they use different vertices. You can see sort of “triangular’ little openings, through which the molecules sooner or later find their way out, and leak.

This is an unfortunate and common feature of CAD models, which often creates this kind of problems. We’ll fix it now…

Test_signelfile_32.jpg: There are different way to fix this kind of leaks. One would be to move a bit along Z one of the two tubes (only one end) generate the circular ends (as done repeatedly before) and then create a short transition between the two. Here I choose another way to do it, to highlight more features of the editor. I select (Smart selection) the first part of the tube, and deleted all facets.

Test_signelfile_33.jpg: done. I will now move the circular end of the other pipe, on the right, BACK (in the –Z direction) up to the Z coordinate of the square facet with hole of the box.

Test_signelfile_34.jpg: again, select the vertices of and create the opening (with opacity=0), after having run the “”Clear isolated” command in the “Vertex” menu (to remove all unneeded vertices, some of them are at the same Z coordinate as those I need to create this facet).

Test_signelfile_35.jpg: I will move the new circular facet at the correct Z coordinate value, of the box, which is Z=10.46296005 (select the facet and use the “Cood.” Button on the menu on the right.

Test_signelfile_36.jpg: I select the facet, hit the “Z” button and copy-paste the new Z coordinate value in the “New coordinate” field. Then hit “OK”. When you hit “Apply” the circular end moves to the correct position. Remember to save often the file, since most commands have no restore option!

Test_signelfile_37.jpg: done.

Test_signelfile_38.jpg: set “Volume” view on, rotate the model, and run again. Now there are leaks through the tiny triangular opening between the walls of the pipe I just made longer and the existing, original square facet with hole.

Test_signelfile_39.jpg: now I need to remove the end facet with hole on the box, and create a new one using the circular opening of the lengthened pipe. I select the facet, no.3480, and delete it.

Test_signelfile_40.jpg: after I delete it, I use the vertex selection mode (keep “Tab” key pressed while selecting with the mouse). I see immediately that there are unwanted vertices, belonging to the old circular opening in the square facet, which need to be removed. I use the “Clear unused” command again.

Test_signelfile_41.jpg: I need to create the square with hole facet: I first need to create the square, which is done by selecting the 4 vertices and using CTRL-v (sorry, didn’t capture the screen here). When you do that you select then the circle and the square, and use the “Create two facets…” “Difference”… “Auto” command, which automatically generates a square facet with a hole in it, as needed.

Test_signelfile_42.jpg: done.

Test_signelfile_43.jpg: Remember to remove the square facet of the step before, since it is not needed anymore (or leave it there but change its opacity to 0, so it won’t bother molecules).

Test_signelfile_44.jpg: now save the file and run it again. NO LEAKS!

I stop here, even if the job is not finished: what needs to be done is to move appropriately some of the end facets (circular) created before. Why is that? Because I created the 4 circular facet on the 6-way cross at the end of the 4 cylindrical arms, but in reality the flanges which I have deleted at each of these 4 ends made the real cylindrical part a bit longer (roughly ½ the flange width). The same for the end of the tube, where also a flange was placed in the original STL model.

So, to get the final simplified (and highly realistic albeit not perfect) geometry you need to read the Z, X and Y coordinates of each of these 5 circular ends and MOVE them to the right coordinates, same as done above in screenshots 35-36.

End.

GalWiner.7z (9.0 MB)